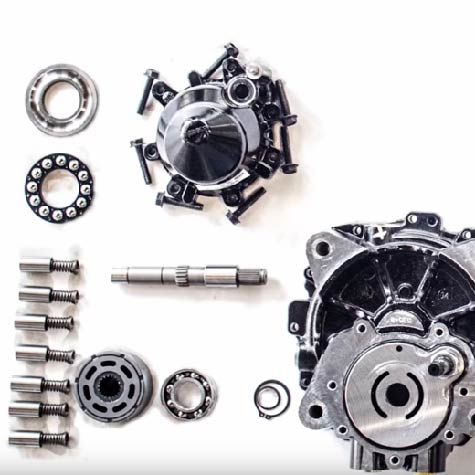

Commercial Mower Clutch

The Wright Parts

The clutch engages the blades, and is engaged more often on stand-on machines than on other style mowers. By spec'ing larger clutches than those on typical mowers, Wright lowers your operating costs.

We spec both Warner and Ogura clutches on all Wright mowers. After dyno testing several clutches for each new application, we select the one that lasts the longest, stops fastest, and has the lowest lifecycle cost per clutch/brake cycle. The average clutch cycle will cost you about a half cent. Both Warner and Ogura offer brake adjustment or shim adjustment, although most of the time, readjusting the clutch results in extending the life by only a small amount. Most clutches wear out on the brake side rather than the clutch side. Reducing the throttle will extend the life of the brake when you turn off the blades but will waste your time. All Wright mowers are approved for full power engagement because we want you to get the job done faster.

The popular clutches available include:

GT 190 lb-ft Adjustable air gap Warner RMS 61-80 lb-ft Residential GT1A 110 lb-ft Adjustable air gap GT1.5 118 lb-ft Flip-set brake Warner TG AL-core 105 lb-ft (Stander B) GT2.5 150 lb-ft Adjustable air gap Warner TG CU-core 125 lb-ft (Intensity, ZTO, Walk behinds, Small Frame Stander®) GT2.75 206 lb-ft Flip-set brake Warner CMS 200 lb-ft Flip-set brake. (X models, Large Frame Standers, MMZ) GT3.5 300 lb-ft Adjustable air gap (ZK) Warner CMS250 250 lb-ft Adjustable shim gap GT5 400 lb-ft Adjustable air gap